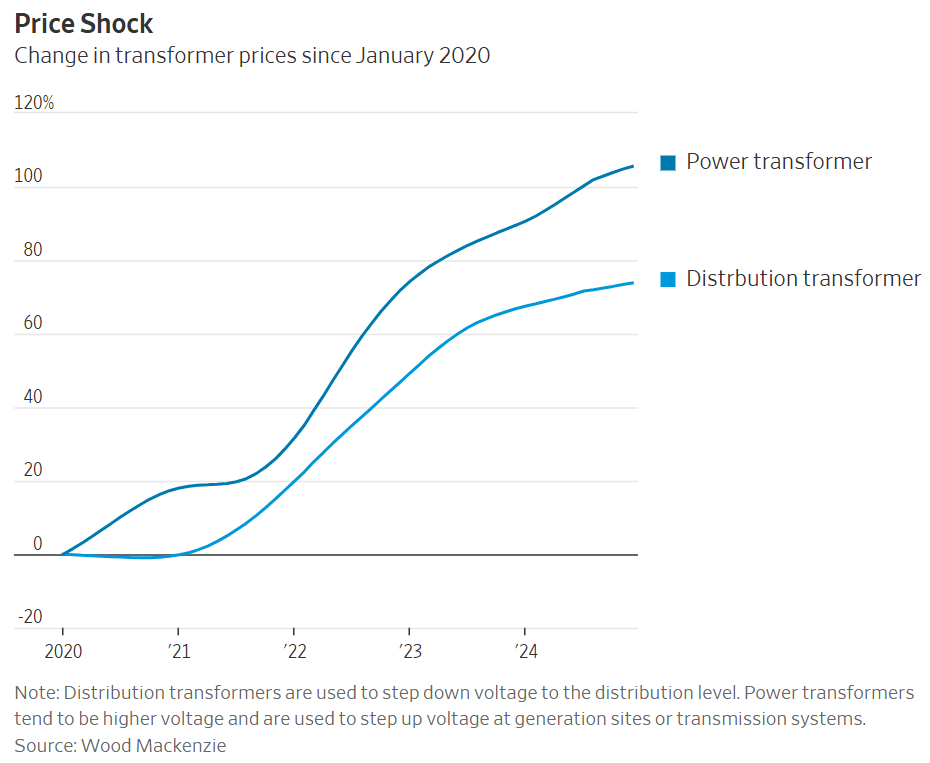

Project developers and utilities need more certainty around infrastructure procurement to meet the rapid growth in electricity demand and increasing renewables deployment. Distribution transformers – the key piece of equipment connecting resources and loads to the grid have a one year lead time. Only about 20% of transformer demand can be met by the domestic supply chain, according to Wood Mackenzie, which also estimated that transformer prices have already risen 70% to 100% since January 2020 because of inflation for raw materials such as electrical steel and copper. In 2024, China accounted for over 32% of U.S. low-voltage transformer equipment imports. Grain-oriented electrical steel (GOES), a key component of transformers has only a single U.S. based source. Although reshoring and U.S. transformer manufacturing capacity increases are in progress, it will still not be enough to become self-sufficient

Unlike traditional low frequency distribution transformers, Alderbuck’s solid state transformer and power conversion systems do not rely on GOES, and systems are manufactured in the United States. Our solutions reduce supply chain uncertainty, are not beholden to tariffs, and reduce lead times by up to 50%.